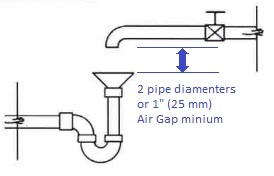

Air Gap (AG)

A method of preventing backflow by using the unobstructed vertical distance between the lowest opening of any pipe or faucet supplying potable water and the flood-level rim of any receiving vessel, such as a tank, pool or fixture. An "approved" air gap separation must be at least twice the effective opening (the inside diameter) of the supply line piping, but never less than one inch.

Air Gap

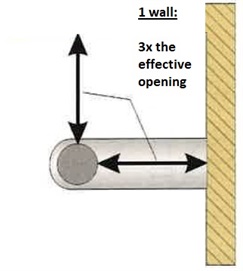

Air Gap with 1 sidewall

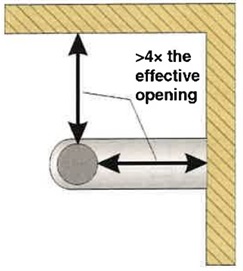

Air Gap with multiple sidewalls

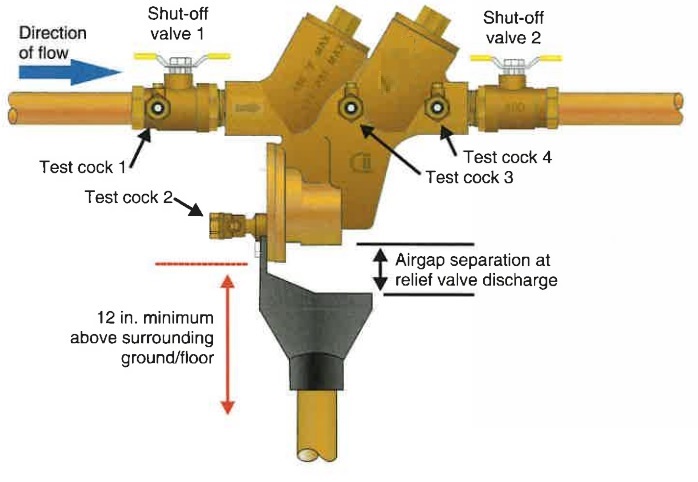

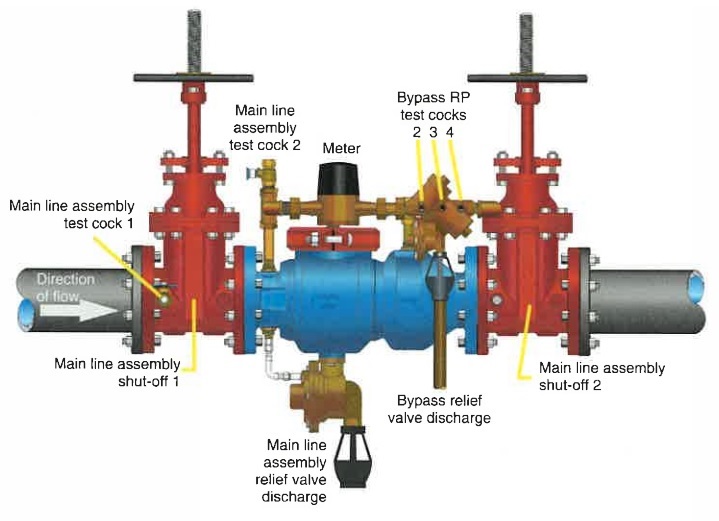

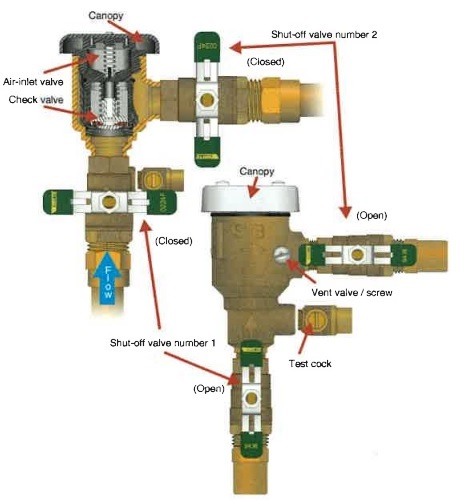

Reduced Pressure Backflow Assembly (RPBA)

An approved assembly providing protection against both backpressure and backpressure, as well as health and non-health hazards. A reduced-pressure principle backflow prevention assembly consists of two independently acting internally loaded check valves, a differential pressure-relief valve, four properly located test cocks, and two isolation valves.

The reduced pressure principle backflow prevention assembly is referred to as the RP, RPPZ, RPZ as well as other acronyms. The RP is the best mechanical backflow preventer available today. It is considered as proper protection for high- or low-hazard applications, backpressure or backsiphonage backflow and containment or isolation protection.

The name of this assembly is derived from a zone of reduced pressure needed for the operation of the relief or vent valve. This device is an assembly of two internally loaded, specially designed and independently operating check valves that have a relief valve installed between the primary valves, specifically designed to maintain a zone of relative differential pressure between the two check valves unless one or both of the check valves are fouled.

Reduced Pressure Backflow Assembly (RPBA)

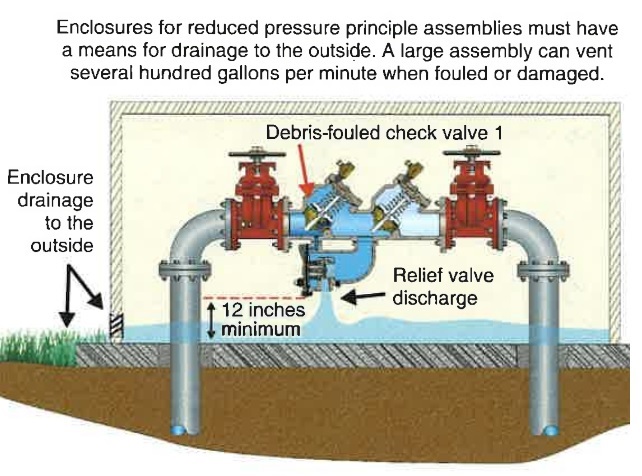

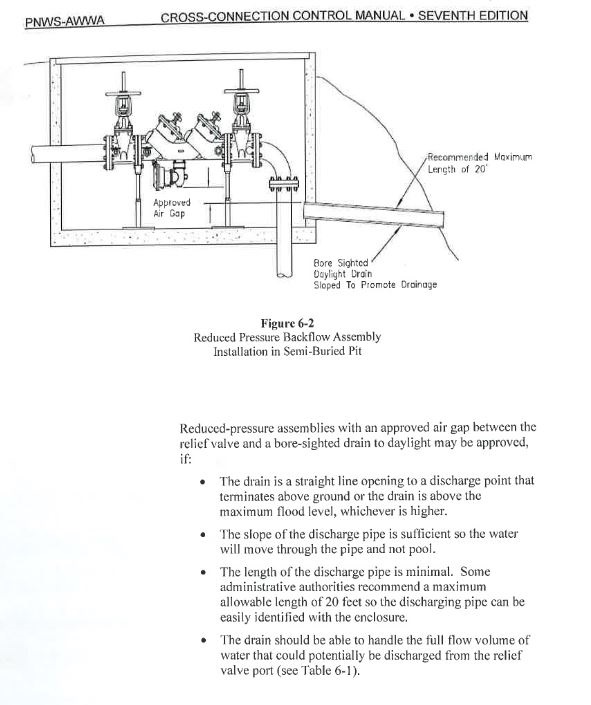

Reduced Pressure Backflow Assembly (RPBA) Outside Enclosure

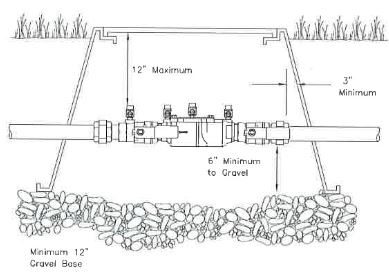

Reduced Pressure Backflow Assembly (RPBA) PNW-AWWA Vault Standard

Reduced Pressure Detector Assembly (RPDA)

This standard applies to the two types of assemblies, identified as:

(a) Reduced Pressure Detector Assembly (RPDA); and

(b) Reduced Pressure Detector Assembly Type II (RPDA-II).

The RPDA and RPDA-II assemblies consist of two (2) independently acting check valves, internally force loaded to a normally closed position, and separated by an intermediate chamber (or zone) in which there is a hydraulically operated relief means for venting to atmosphere, internally force loaded to a normally open position. These assemblies are designed to operate under continuous pressure conditions. The assembly includes two (2) properly located, tightly closing shut-off valves and properly located test cocks. The assemblies also include a bypass line which provides a visual or audible indication of system leakage or unauthorized use of water.

Reduced Pressure Detector Assembly (RPDA)

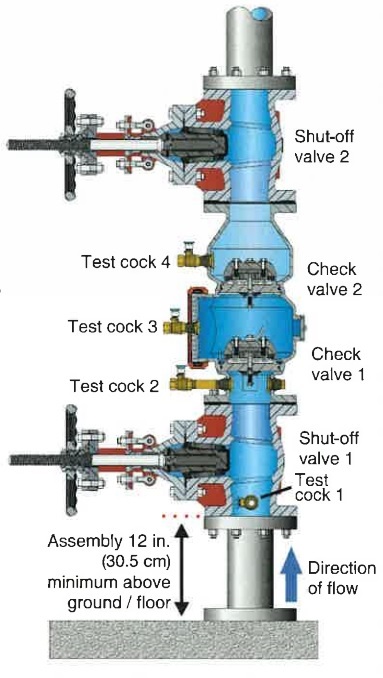

Double Check Valve Backflow Assembly (DCVA)

An approved assembly designed to protect against both backsiphonage and backpressure that are subject to low health hazard conditions. The Double Check Valve Assembly (DCVA) is an approved backflow assembly consisting of two single check valves assembled within one body and furnished with four test cocks and two shut-off valves. Double checks are commonly used to protect against low to medium hazard installations such as food processing equipment or lawn sprinkler systems.

Double Check Valve Assembly (Irrigation Installation)

Double Check Valve Backflow Assembly (DCVA)

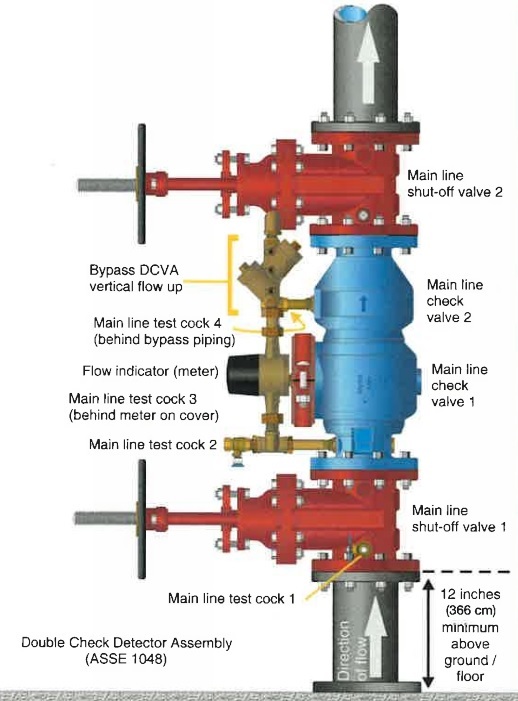

Double Check Detector Assembly (DCDA)

An approved assembly designed to protect against both backsiphonage and backpressure that are subject to low health hazard conditions. This standard applies to Double Check Detector Assembly (DCDA) and Double Check Detector Assembly Type II (DCDA-II). The DCDA and DCDA-II assemblies consist of two (2) independently acting check valves, internally force loaded to a normally closed position. These assemblies are designed to operate under continuous pressure conditions. The assembly shall include two (2) properly located, tightly closing shut-off valves and properly located test cocks. The assemblies also include a bypass line which provides a visual or audible indication of system leakage or unauthorized use of water. This standard also applies to Manifold Double Check Detector Assemblies consisting of two (2) or more complete DCDA or DCDA-II assemblies in parallel.

Double Check Detector Assembly (DCDA)

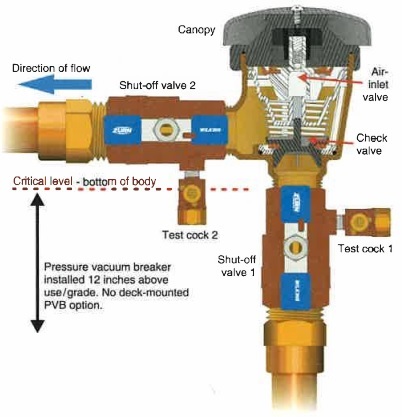

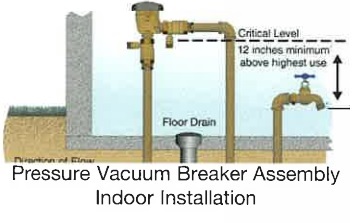

Pressure Vacuum Breaker (PVB)

An approved assembly installed in water supply lines to prevent the entrance of non-potable material into the potable water supply by backsiphonage (only) and are intended for use in both high and low hazard applications.

Pressure Vacuum Breaker (PVB)

Spill Resistant Vacuum Breaker (SVB)

An approved assembly designed to protect against backsiphonage only in low and high health hazard conditions. The SVB is similar to the PVB, however it is designed to be spill-resistant for indoor use. Like the PVB, the SVB is designed to protect against backsiphonage and is not to be subjected to backpressure. Typically, the SVB is installed on chemical-soap dispensers, x-ray supply lines or tank fills.

Spill Resistant Vacuum Breaker (SVB)